| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : VIIPLUS

Model Number : Bimetal Bushing

Certification : ISO 9001

Place of Origin : Bimetal Bearing Manufacturers

MOQ : negotiable

Price : Negotiable

Payment Terms : MoneyGram, Western Union, T/T

Supply Ability : casting bimetal bushing, China, manufacturers, suppliers, factory, wholesale, Metric Self Lubricating Bushing, Self Lubricating Bushings, Journal Bronze Bearings, Bimetal With Graphite Bearing, Metallic Bearings, Flanged Bimetallic Plain Bearing

Delivery Time : 7-25 work days

Packaging Details : EXPORT CARTON WOOD PALLET WOODEN CASE

BiMetal Bushings Material : Bimetal Bearing

Application : throttle valve ,shaft,Throttle Lever

Bushing Feature : High Hardness

Copper : CuSn10Pb10,other

Type : Bi-Metallic Composite Bearings

Feature : maintenance-free ,Tin Bronze Lead

Item : auto bushing

Size : metric size

Bearing Bushing Factory Price : tiffany@viiplus.com

Self-lubricating Bearing Bushing Manufacturer : https://www.viiplus.com/

High Light : Steel Backed Bronze Bushing, Bimetallic Bushes

Bimetallic Bearing Bushing : Bimetal bearing with steel backing and bronze overlay • Particularly suitable for high ... Bimetal plain bearings to standard SAE 792

Bush Bearings Manufacturers Suppliers Exporters : plain bearings. Long, maintenance-free service, manufactures bushings in various designs and from different materials. tiffany@viiplus.com, Bushings - Configure and purchase - https://www.viiplus.com/

Heavy Metal Bushings are precision-manufactured components designed specifically for use in throttle valves. These bushings feature a bimetal construction, which combines the strengths of two different metals to create a bushing that is both durable and highly wear-resistant.

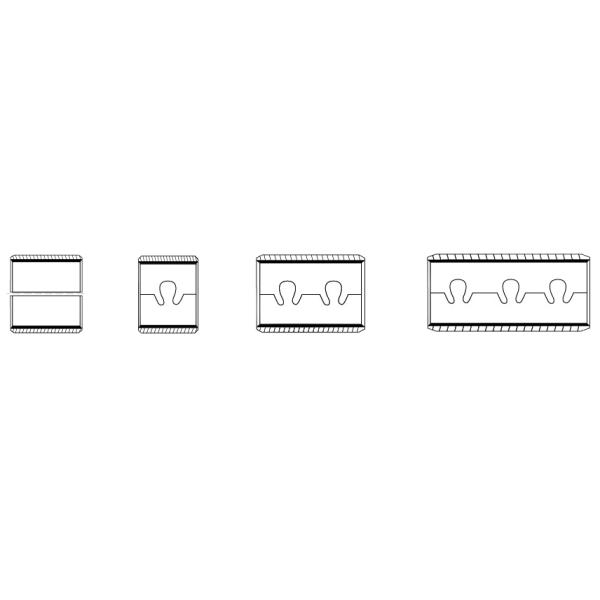

The split type design of these bushings allows for easy installation and removal, making maintenance and replacement quick and efficient. The bushings are also equipped with grooves in either the JF800 or JF720 pattern, depending on the specific application requirements. These grooves provide additional lubrication and reduce friction, further enhancing the bushings' performance and lifespan.

The Heavy Metal Bushings are made from high-quality materials that can withstand the high pressures and temperatures commonly encountered in throttle valve applications. This ensures reliable performance even under extreme conditions.

Wh you're looking to replace worn-out bushings or upgrade your throttle valve system, our Heavy Metal Bushings with bimetal construction and JF800/JF720 grooves are an excellent choice. They offer superior performance, durability, and ease of maintenance, making them a valuable addition to any throttle valve setup.

Professional metal and bimetal bearing manufacturer,Bimetal Bearing, Diameter Range : 15 to 130 mm, jf-800 bimetallic bearing, is based on low carbon steel plate as matrix material, surface sintering CuPb10Sn10 or CuSn6Zn6Pb3 steel and copper alloy products.This product is one of the strongest bearing capacity of double alloy bearings, used for the balance bridge bushing of heavy duty vehicles.It is a kind of high - load and low - speed motion bearing.Technical parameters

Alloy layer material

Maximum bearing pressure 65N/mm2

The highest operating temperature is 260 ℃

Alloy layer hardness (70~100)HB

|

Norminal Thickness |

Tolerances of Series B (non-machinable) |

Tolerances of Series C (non-machinable) |

|---|---|---|

| 1.0 | -0.025 | +0.25 +0.15 |

| 1.5 | -0.030 | +0.25 +0.15 |

| 2.0 | -0.035 | +0.25 +0.15 |

| 2.5 | -0.040 | +0.30 +0.15 |

| 3.0 | -0.045 | +0.30 +0.15 |

| 3.5 | -0.050 | +0.30 +0.15 |

| Norminal Thickness |

Tolerances of Series B (non-machinable) |

Tolerances of Series C (non-machinable) |

|---|---|---|

| 1.0 | -0.025 | +0.25 +0.15 |

| 1.5 | -0.030 | +0.25 +0.15 |

| 2.0 | -0.035 | +0.25 +0.15 |

| 2.5 | -0.040 | +0.30 +0.15 |

| 3.0 | -0.045 | +0.30 +0.15 |

| 3.5 | -0.050 | +0.30 +0.15 |

| CuPb10Sn10 | ||||

| Pb(%) | Fe(%) | Ni(%) | Zn(%) | Cu(%) |

| 8.0-11.0 | ≦0.25 | ≦1.5 | ≦2.0 | 78.0-87.0 |

| d | D | H8 | (H7) | H7 | Wall thickness | H | f1 | f2 | L | ||||||||

| min | max | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | ||||||||

| 10 | 12 | 10-0.022 | 12+0.018 | 0.148 | 0.995 | 0.935 | 4 | 0.5 | 0.3 | 1010 | 1015 | 1020 | |||||

| 12 | 14 | 12-0.027 | 14+0.018 | 0.01 | 1210 | 1215 | 1220 | ||||||||||

| 14 | 16 | 14-0.027 | 16+0.018 | 1410 | 1415 | 1420 | |||||||||||

| 15 | 17 | 15-0.027 | 17+0.018 | 1510 | 1515 | 1520 | |||||||||||

| 16 | 18 | 16-0.027 | 18+0.018 | 0.8 | 0.4 | 1610 | 1615 | 1620 | |||||||||

| 18 | 20 | 18-0.027 | 20+0.021 | 0.151 | 1810 | 1815 | 1820 | 1820 | |||||||||

| 0.01 | |||||||||||||||||

| 20 | 23 | 20-0.033 | 23+0.021 | 0.181 | 1.49 | 1.43 | 2010 | 2015 | 2020 | 2020 | |||||||

| 22 | 25 | 22-0.033 | 25+0.021 | 0.02 | 6 | 2210 | 2215 | 2220 | 2220 | ||||||||

| 24 | 27 | 24-0.033 | 27+0.021 | 1 | 0.5 | 2410 | 2415 | 2420 | 2420 | 2430 | |||||||

| 25 | 28 | 25-0.033 | 28+0.021 | 2515 | 2520 | 2520 | 2530 | ||||||||||

| 26 | 30 | 26-0.033 | 30+0.021 | 0.205 | 1.98 | 1.92 | 2615 | 2620 | 2620 | 2630 | |||||||

| 28 | 32 | 28-0.033 | 32+0.025 | 0.03 | 2815 | 2820 | 2820 | 2830 | 2840 | ||||||||

| 30 | 34 | 30-0.033 | 34+0.025 | 1.2 | 0.6 | 3015 | 3020 | 3020 | 3030 | 3040 | |||||||

| 32 | 36 | 32-0.039 | 36+0.025 | 3215 | 3220 | 3220 | 3230 | 3240 | |||||||||

| 35 | 39 | 35-0.039 | 39+0.025 | 3520 | 3520 | 3530 | 3540 | 3550 | |||||||||

| 38 | 42 | 38-0.039 | 42+0.025 | 8 | 3820 | 3820 | 3830 | 3840 | 3850 | ||||||||

| 40 | 44 | 40-0.039 | 44+0.025 | 4020 | 4020 | 4030 | 4040 | 4050 | |||||||||

| d | D | (h8) | (H7) | H7 ID | Wall thickness | f1 | f2 | L | |||||||||

| min | max | 25 | 30 | 40 | 50 | 60 | 80 | 90 | 100 | ||||||||

| 45 | 50 | 45-0.039 | 50+0.025 | 0.205 | 2.46 | 2.4 | 8 | 1.5 | 1 | 4525 | 4530 | 4540 | 4550 | ||||

| 0.03 | |||||||||||||||||

| 50 | 55 | 50-0.039 | 55+0.030 | 0.21 | 5030 | 5040 | 5050 | 5060 | |||||||||

| 55 | 60 | 55-0.046 | 60+0.030 | 0.03 | 5530 | 5540 | 5550 | 5560 | |||||||||

| 60 | 65 | 60-0.046 | 65+0.030 | 6030 | 6040 | 6050 | 6060 | ||||||||||

| 65 | 70 | 65-0.046 | 70+0.030 | 6530 | 6540 | 6550 | 6560 | ||||||||||

| 70 | 75 | 70-0.046 | 75+0.030 | 7030 | 7040 | 7050 | 7060 | 7080 | |||||||||

| 75 | 80 | 75-0.046 | 80+0.030 | 9.5 | 7530 | 7540 | 7550 | 7560 | |||||||||

| 80 | 85 | 80-0.046 | 85+0.035 | 0.215 | 8040 | 8050 | 8060 | 8080 | |||||||||

| 85 | 90 | 85-0.054 | 90+0.035 | 0.03 | 8530 | 8550 | 8560 | 8580 | 85100 | ||||||||

| 90 | 95 | 90-0.054 | 95+0.035 | 9050 | 9060 | 9080 | 90100 | ||||||||||

| 95 | 100 | 95-0.054 | 100+0.035 | 9060 | 9080 | 9090 | 90100 | ||||||||||

| 100 | 105 | 100-0.054 | 105+0.035 | 10060 | 10080 | 10090 | 100100 | ||||||||||

| 105 | 110 | 105-0.054 | 110+0.035 | 10560 | 10580 | 105100 | |||||||||||

| 110 | 115 | 110-0.054 | 115+0.035 | 11060 | 11080 | 110100 | |||||||||||

| 115 | 120 | 115-0.054 | 120+0.035 | 11550 | 11580 | ||||||||||||

| 120 | 125 | 120-0.054 | 125+0.040 | 0.22 | 12050 | 12060 | 120100 | ||||||||||

| 125 | 130 | 125-0.063 | 130+0.040 | 0.03 | 125100 | ||||||||||||

| 130 | 135 | 130-0.063 | 135+0.040 | 13060 | 130100 | ||||||||||||

| 135 | 140 | 135-0.063 | 140+0.040 | 13560 | 13580 | ||||||||||||

| 140 | 145 | 140-0.063 | 145+0.040 | 14060 | 14080 | 140100 | |||||||||||

| 150 | 155 | 150-0.063 | 155+0.040 | 15060 | 15080 | 150100 | |||||||||||

bimetal bearing BUSHES GROOVES INDENTATIONS

A mid-load capacity & middle anti-fatigue

Applied in middle speed,high impact conditions

Good anti-corrosion,and sliding capability

The products can be use in undercarriage parts and engines of auto industry, construction machine,etc.

| Performance | Data | |

| Max dynamic Load P | 140N/mm² | |

| Max line speed V | Greaes lubrication | 2.5m/s |

| Max PV value | Greaes lubrication | 2.8N/mm²·m/s |

| Friction coef μ | Greaes lubrication | 0.05~0.15 |

| Max line speed V | Oil lubrication | 5m/s |

| Max PV value | Oil lubrication | 10N/mm²· m/s |

| Friction coef μ | Oil lubrication | 0.04~0.12 |

| Max Working temperature | Greaes lubrication | 150℃ |

| Performance | Data | |

| Max Working temperature | Oil lubrication | 250℃ |

| Mating Axis | Hardness | ≥53HB |

| Mating Axis | Roughness | Ra=0.32~0.63 |

| Alloy Hardness | 80~120 | |

| Heat-conducting Coefficient | 47W/(m·k) | |

| Coefficient of linear xpansion | 18×10-6K-1 | |

| according to customers special request while out of this table. | ||

|

|

Heavy Metal Bushings Bimetal Bushes Jf800 Jf720 Grooves Split Type For Throttle Valve Images |